- Howie Fenton

- |

- March 04, 2025

The global printing market is set for an upturn.

Market research tells us it’s expected to reach approximately $357.8 billion in 2025, with a compound annual growth rate (CAGR) of 5.4%. But not every print business will benefit from that growth, predicts Andy Paparozzi from NAPCO.

“The upturn is likely to be substantial and extended but will not be inclusive,” he says. “Participation will be limited to companies that use all the tools available.”

That includes businesses that embrace transformative change. After all, in today’s evolving print industry, efficiency, cost reduction, and scalability are more critical than ever. But traditional print workflows, often burdened by manual processes and inefficiencies, struggle to keep up with increasing demand.

Technologies like print workflow automation transform the industry by enabling businesses to streamline operations, reduce costs, and improve quality control. All of which sets you up for growth.

This article explores the financial benefits of print workflow automation, key technologies driving efficiency, and how automation can position print businesses for long-term growth — as well as how the right quality control procedure can help add to your advantage.

What Are the Benefits of Automating Your Print Workflow?

So how can print workflow automation help you grow your business and set you up to take advantage of the expanding print market? There are three primary ways:

1. Increased Efficiency

Manual print workflows involve multiple steps — from order intake to finishing. Each can slow production and introduce errors. Automation eliminates bottlenecks and inefficiencies, enabling faster job completion and improved customer satisfaction.

For example, RSA’s WebCRD, a Web to Print platform, allows businesses to process print orders online, automatically schedule jobs, and streamline production workflows. Web to Print automation solutions optimize production schedules, ensuring print jobs move seamlessly through the pipeline. The impact is faster turnaround times, which allow businesses to handle more orders, reduce labor costs, and increase revenue. Automating online ordering reduces the time needed to create the job ticket, eliminates most estimating, and can drastically reduce the billing process time.

Citrus College, a community college in California, was able to accomplish a 50% improvement in job turnaround with WebCRD, as well as a 17% volume increase – all without adding staff. “It’s a win/win,” says Rocky Reynolds, Supervisor of Reprographics/Mail at Citrus. “Our customers can submit and track jobs online and we are faster because we get fewer walk ins and interruptions. Our staff can just do what they do and get the work done."

2. Reduced Costs

By automating labor-intensive tasks, print businesses can:

- Lower labor expenses: Automated job submission, scheduling, and processing reduce the need for manual intervention, cutting administrative costs.

- Optimize materials: Intelligent job batching and routing ensure minimal material waste, lowering overhead costs.

- Ensure efficiency: Intelligence-driven print management optimizes equipment usage, reducing electricity and maintenance costs.

For example, RSA’s QDirect output management software routes jobs efficiently across multiple devices, maximizing equipment utilization. This means businesses can reduce printer downtime, lower consumable costs, and enhance productivity. The impact of reduced costs directly improves your ability to meet your financial objectives.

Take The Center for Disability Services in Albany, New York, for instance. After introducing QDirect, Director of Operations Chris Schelin says their team can focus on releasing all jobs to their 12 printers, which opens up the potential for new work. “With QDirect's level of automation, our shop can now take on clients with smaller jobs today and hopefully turn them into larger clients down the line,” Schelin adds.

3. Improved Accuracy and Reduced Rework

Errors in print production lead to expensive reprints, wasted materials, and missed deadlines. Automated workflows ensure consistency, accuracy, and compliance with customer requirements. The impact is fewer mistakes, which means lower material waste, improved turnaround times, and better customer satisfaction.

One tool to help reduce rework is RSA’s ReadyPrint, which automates file preparation, imposition, and proofing, reducing human errors.

Creating a Quality Control Procedure

Of course, technology is just the beginning. A quality control procedure – even one that’s decidedly low-tech – can also help you get more from your business, with less rework required.

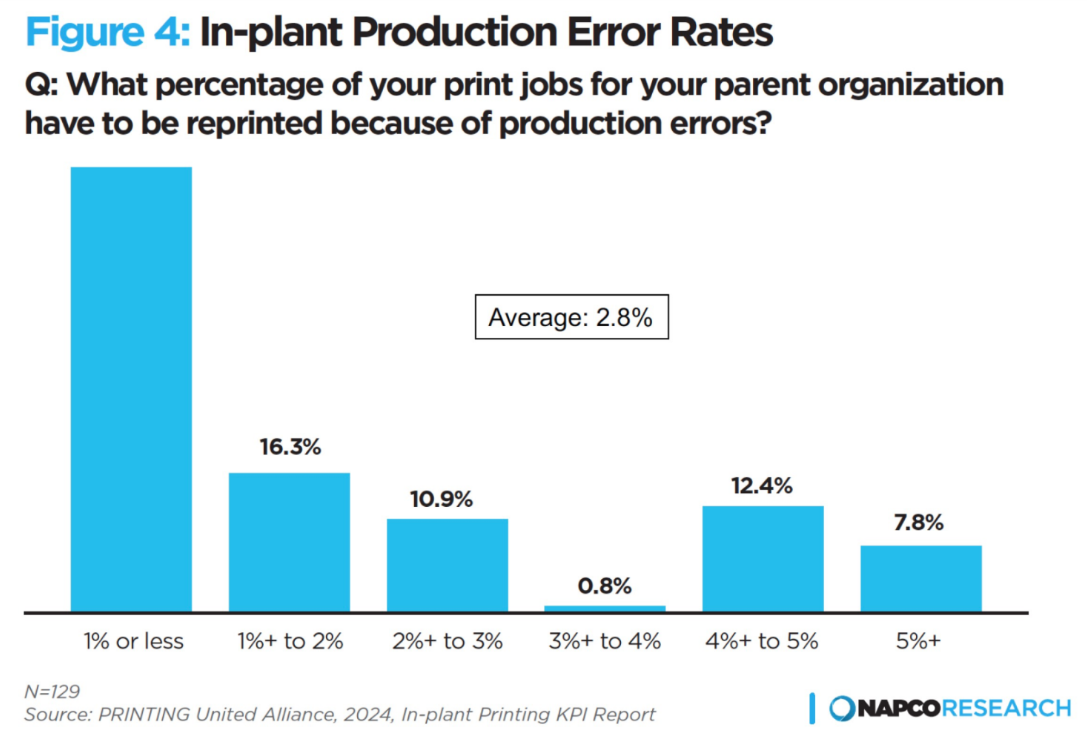

Do you suspect you have higher-than-normal rework? Looking at the NAPCO chart below, 1% or less rework is worldclass, 1-4% is industry average, and 5% or higher requires action.

If you think you have a quality control issue, measuring your rework is a good place to start. It’s not hard. It just starts with communication. In other words, you have to tell everyone in production where you want them to store the bad work. And every time a mistake occurs, you simply add it to the pile. At the end of each month, you can create categories of why the work went wrong (image streaking, incorrect color, incorrect finishing, and so on).

Then, calculate the percentage of rework. This can be represented by the percentage of jobs or the percentage of money wasted. What matters is reducing the percentage of rework. Each month, find the category of work with the most significant percentage of mistakes, review the problems, discuss how to avoid them, and meet with staff to work on eliminating those issues.

Conclusion

With the global printing industry reaching $357.8 billion in 2025, automation is no longer optional — it’s a necessity for businesses aiming to increase efficiency, reduce costs, and stay competitive. Tools like RSA’s WebCRD, QDirect, and ReadyPrint provide end-to-end workflow enhancements that drive profitability and help reach those goals.

By integrating intelligent print management, automated prepress tools, and Web to Print platforms, businesses can reduce costs, improve quality, and scale operations effortlessly. Whether you're in commercial printing, packaging, or industrial applications, workflow automation is the key to long-term success. In addition, if you suspect your rework percentage is high, you should measure it — a simple quality control process may be what you need to get it within the industry average or up to world-class performance

So, are you ready to transform your print workflow and maximize your ROI? Start measuring and automating today and lead the future of print production!

Enhancing Your Print Workflow: The Keys to Efficiency and Growth

To stay competitive in the current global printing market, and take advantage of the upturn expected in 2025, print businesses need to embrace print workflow automation. By adding efficiencies, reducing costs, and improving accuracy, print workflow automation can help print businesses achieve their goals and grow their profits. And a quality control procedure that measures ongoing waste can help add to that advantage.